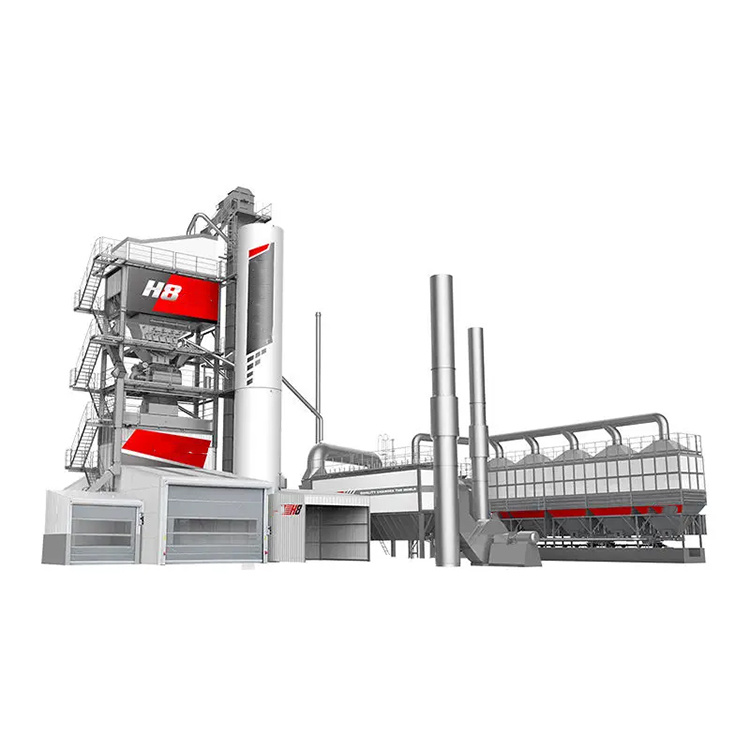

90m3 Mobile Concrete Batching Plant

90m3 Mobile Concrete Batching Plant image

Basic Info.

Product Description

HZS series hopper lift concrete batching plant, belongs to compulsory and high efficiency equipment, it can produce various kinds of concrete including quaking concrete and hard concrete, with high productive efficiency, it is widely used in medium scale building works, road and bridge works and concrete products prefabricating plants, and is an ideal equipment to produce commercial used concrete. The main machine of this series use JS series double shaft compulsory mixer, it can mix concrete evenly, with a short period of mixing, long life wearing parts, it can be operated and maintained conveniently, it used control technology with newest design concept, for example: electric weighing,computer control, and digital display, etc., electric weighing has been equipped with buffer device and auto compensation function and the measure precision is high. Equipped with maintenance sidewalk, it is the ideal selection for the construction units to produce high quality concrete.

| Model | HZS90 |

| Capacity | 90m³/h |

| Mixer | JS1500 Twin-Shaft Concrete Mixer,1.5m³/batch,60s/batch |

| Weighing Precision | Aggregate:3000kg,±2%;Cement:800kg,±1%;Water:400kg,±1% |

| Aggregate Size | 80/100mm |

| Unloading Height | 4200mm |

| Operation | Full Auto PLC Control |

| Installation Power | 145kw |

| Dimensions | 45000x23000x12000mm |

| Electrical Design | 220V/380V-50Hz |

| Documents | Lay-Out/ Electric Circuit Diagram; Chinese-English Operation Manual; Qualification Certificate |

| HZS90 | Specification | |

| 1.Aggregate Supplying System PLD2400 | 3 bins aggregate storage bins , total volume:15m³X3=45 m³ | |

| pneumatic discharge, cylinder: 9units | ||

| aggregate weighing hopper 1.2m³X3,weighing sensor capacity : 1000kgX12; flat belt conveyor(B=800) ,motor power :11kw | ||

| 2. JS1500 Twin Shaft Concrete Mixer (hydraulic discharging) | JS1500B twin shaft concrete mixer ,1.5m³/batch,90m³/hr. | |

| mixer volume2400L,mixing shaft 2pcs , mixing paddle 2X6pcs | ||

| transmission system, motor power:30kwX2,mixing speed 24r/min | ||

| weight 6500kg | ||

| hydraulic discharging unit 1 set; 2.2kw | ||

| lubrication system 1 set | ||

| sealing system for the shaft-end | ||

| 3.Main Frame & Closed Frame | mixing tower support feet | |

| mixing section structure | ||

| weighing section structure | ||

| ladder, guardrail | ||

| platform | ||

| discharging chute, unloading height 4200mm | ||

| color keep warm closed wall and frame | ||

| dust collector | ||

| 4.Aggregate Belt Conveyor & Temporary Storage Bin | belt conveyor:width:800mm, feeding speed:2m/s, motor power:37kw | |

| framework | ||

| rain cover | ||

| bilateral service platform | ||

| roller | ||

| temporary storage bin 2.4m3 | ||

| 5. Cement Weighing System | A set of 100T cement silo with legs/ dust collector/ breaking device/ level indicator | |

| Φ273X9000mm screw conveyors for cement, motor power 15kw; | ||

| cement weighting hopper :800kg; cement weighing sensor :500kgX3;discharging valve Φ300mm;weighing precision : ±1% | ||

| 6. Water Weighing System | water pump flow rate:60m³/h,motor power 5.5kw | |

| water tank 2.0m3, pipe line and valve | ||

| water weighting hopper :400kg; water weighing sensor :500kgX3;weighing precision : ±1% | ||

| 7. Additive Supply System | additive mixer tank:1m3 | |

| additive pump flow rate:10m³/h,motor power 0.55kw | ||

| pipe line and valve | ||

| additive weighting hopper :70kg; additive weighing sensor :50kgX3;weighing precision : ±1% | ||

| 8.Coal Ash Weighing System | coal ash weighting hopper :400kg; coal ash weighing sensor :500kgX3;discharging valve Φ300mm;weighing precision : ±1% | |

| 9.Pneumatic System | air compressor, flow rate 2.0m³/min,motor power 15kw | |

| air storage tank 0.6m3 | ||

| pipe line ,solenoid valve | ||

| 10. PLC Control System | control room (9m2) | |

| electrical control cabinet | ||

| control computer | ||

| electric element (SCHNEIDER) | ||

| 17" Displayer | ||

| printer | ||

| wire and cable | ||

| frame work | ||

| air condition |

We are China 90m3 Mobile Concrete Batching Plant manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Tags: Asphalt Batching Plant, Asphalt Mixing Plant, Concrete Mixer